Engineering Services

In addition to technology and equipment solutions, AMS provides a suite of Engineering Services ranging from feasibility studies to detailed design and customized control system solutions. We specialize in basic engineering packages and have reference packages and operational data for the following facilities:

240,000MTA trichlorosilane plant

12,000MTA monosilane plant

10,000MTA polysilicon plant

400MTA electronic grade silicon gas precursor A facility

100MTA silicon gas precursor B facility

50MTA silicon gas precursor C facility

20MTA electronic grade silicon gas precursor C facility

Electronic grade CVD reactor

Our Engineering Services are

tailored to each client’s needs

Feasibility Studies

Comparative evaluation of technologies

Flow scheme development and evaluation

Material balance, energy usage, and raw materials usage

Economic evaluation for investment and operating costs

Basic Engineering

Basis of Design

Process Flow Diagrams (PFDs)

Process Description

Heat and Material Balance

Utility Requirements

Preliminary Layout

Waste Stream Summary

Piping and Instrumentation Diagrams (P&IDs)

Equipment Process Specifications

Process Control Description

Cause and Effect Matrix

Equipment List

Process Instrument Data

PSV Loads

Pipe Specifications

Notes to DEC

Operating Guidelines

Detailed Engineering

3D Layouts

Piping and Valve Specifications

Preliminary Isometrics

Material Take Offs

Electrical Diagrams

Fabrication Drawings

Fabrication Test and Inspection Plans

Turnkey Solutions

Reactors

Purification systems

Tankage

Filling systems

Laboratories

Specialty gas Production facilities

Control systems

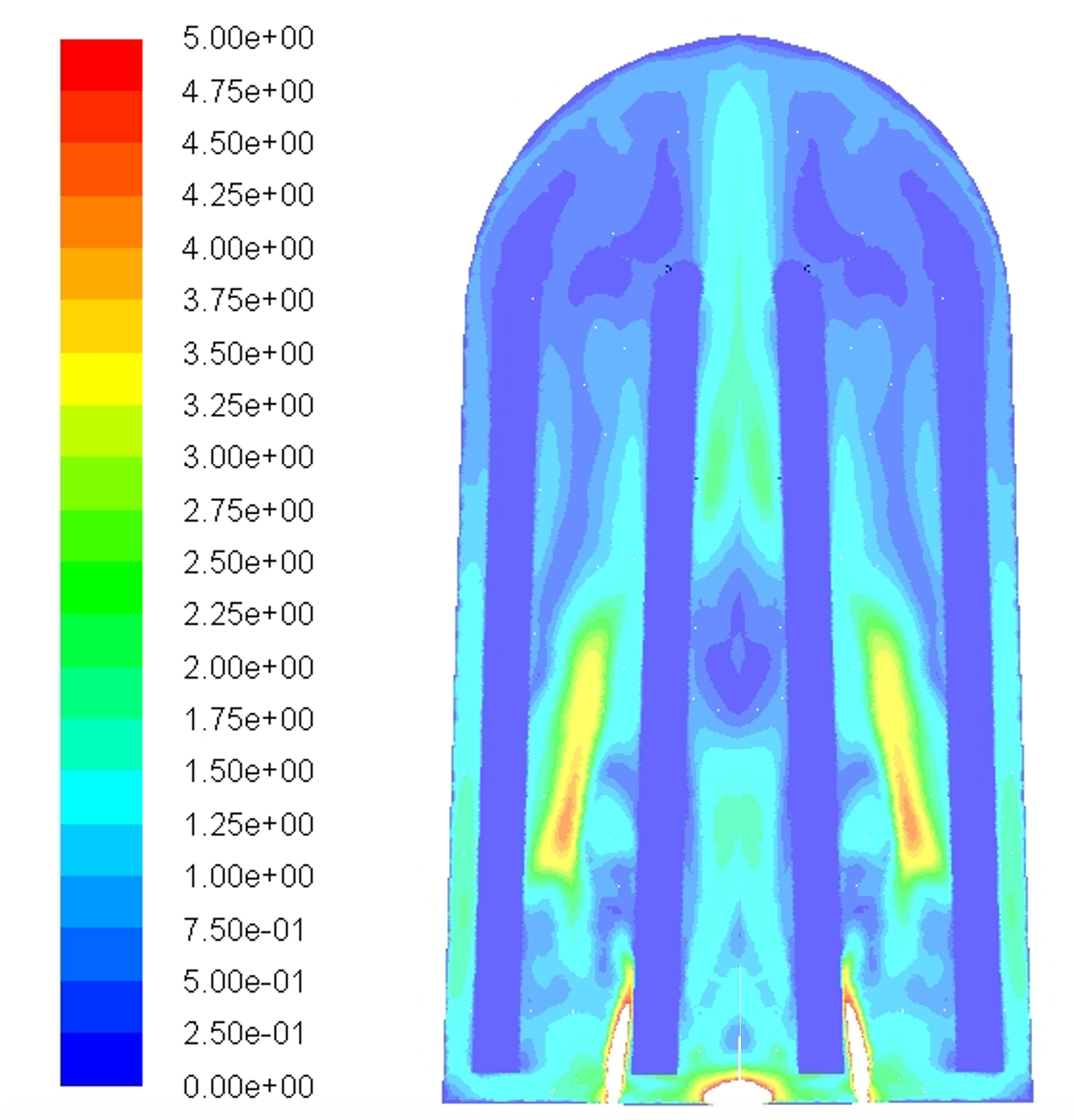

Process Modeling

AMS has expertise and software to conduct detailed heat transfer, process, and flow modeling. Our capabilities include Computational Fluid Dynamics and Steady-State Process Modeling.

AMS has contracted with and provides engineering and technical expertise to top-tier polysilicon producers, specialty gas producers/distributors, and energy storage companies.

Engineering References

Electronic grade polysilicon producer - Japan

Feasibility study for battery material producer - USA

Specialty gases extraction and purification facility - China

Specialty gases filling systems - China

Specialty gases ultra-high purity purification unit - South Korea

Silane plant - South Korea

Turnkey silane purification unit - China

Electronic grade polysilicon reactor - Asia

Silane feasibility study - Japan

Turnkey specialty gases synthesis facility - USA

Chlorosilane manufacturing facility - Taiwan

Tier 1 polysilicon producer - Xinjiang, China