Filling Systems

AMS personnel are recognized experts in handling toxic and flammable specialty gases, designing facilities to fill containers, auditing, and operating these facilities. AMS designs and provides turnkey solutions to fill compressed gases, liquified gases, and liquid specialty gas containers.

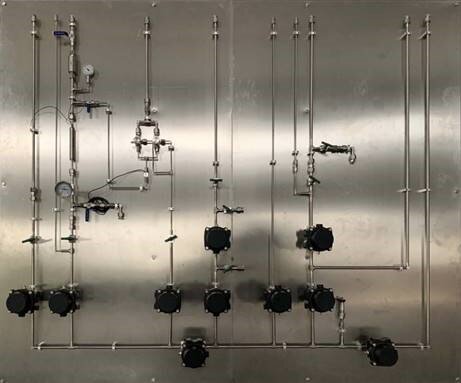

A critical piece of equipment is the filling system. AMS has designed, shipped, installed and commissioned liquified and compressed silicon gas filling systems for international customers. Our designs incorporate the latest in safety engineering to ensure reliable, consistent operation.

AMS specializes in turnkey systems that integrate the equipment and automation to fill specialty gas containers.

Equipment

In order for gas companies to add value in the supply chain, it is typical to ship large containers to regional transfills where smaller containers are loaded for delivery to end users. The proper design of these systems is critical in preventing accidents and maintaining high product quality.

An important step in specialty gas manufacturing is to load or fill gases into transportation approved containers built for use at fabs. By leveraging our fabrication partners in the USA and throughout Asia we can design, procure, build, and deliver systems to meet the needs of the most demanding customers.

Automation

The successful operation of a filling system is highly dependent on the human component. AMS can match a customized, automated interface to the equipment with all the I/O required to give customers an unparalleled experience with integration.

While there are many hardware providers in the market, the key value AMS brings is custom programming to provide customers the right fill sequence for the application. AMS specializes in programmable logic controllers (PLC) and Human Machine Interface (HMI)programming for specialty gas filling systems. These systems reduce risk, limit the potential for mistakes, and improve consistency of the process. The custom programmed sequence guides the operator through the process of filling containers from inspection to shipment.

By automating many of the steps and providing the correct instructions at the right time, the programming provided by AMS serves as a tool to reduces safety risk, increase repeatability, and ensure quality expectations are met with the flexibility to change as needed. AMS’s solution has been proven at several operating locations with international regulations and standards.

AMS designs, specifies, programs and ships HMI/PLC packages to match customer’s existing equipment or installs a complete turnkey solution at the facility.

Key Features

Automatic emergency shut down

Dual language option

Flexibility to make changes as needed

Remote monitoring

Data historian

Traceability

Custom add-ons

Task specific instructions

On-site and remote support